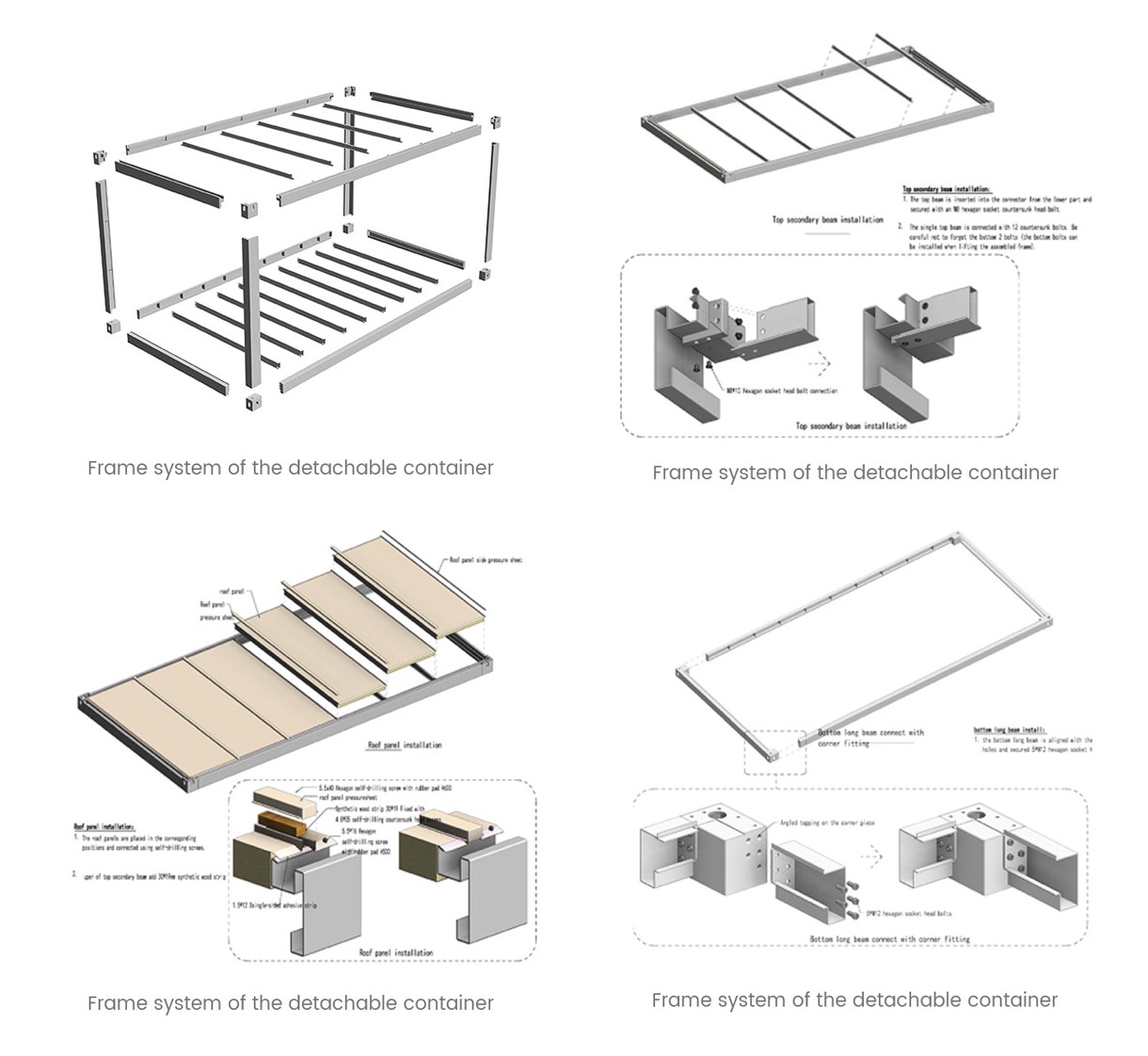

Detachable is a cost-saving version of flatpack. We change the roof insulation to glass wool or rockwool, make them into small pieces and can be easily assembled onsite, we‘ll send all steel members prefabricated with connections ready to be bolt together, we provide also very detailed assemble instructions.

|

Item |

Specifications |

||

|

External Dimensions(L*W"H) |

L6000*W3000*H2700mm; L12000*W3000*H2700mm; or customized dimensions for special projects |

||

|

Main frame |

2.2~3mm thick Q355 low alloy carbon galvanized cold rolled profiled steel, to be assembled onsite |

||

|

Wall panel |

Sandwich panel with 0.4mm color bond steel on both sides, Core material options: EPS/Glass wool/ Rock wool/PU Thickness options: 50/75/100mm |

||

|

Roof panel |

Sandwich panel with 0.4mm color bond steel on both sides, Core material options: Glass wool/ Rock wool Thickness: 70~100mm |

||

|

Floor |

Cement fiber board / MGO board + PVC |

||

|

Window |

Sliding window with alu. Or PVC frame: 980*1150mm Option: fly screen, security steel bar, rolling blind |

||

|

Door |

Security door/Sandwich panel door/alu. Frame glass door: 960*2080mm |

||

|

Loading |

6 sets in a 20GP, 12 sets in a 40HQ |

||

|

Color |

Red, white, black, blue or customized |

||

|

Corner post |

T=4.5mm cold rolled steel profile, galvanized, full welded, dimension is 160mm*160mm |

||

|

Electricity |

Light, Switch, Socket, distribution box, breaker and wire |

||

|

Painting |

Baking paint spray molding on well-polished galvanized steel |

||

|

Technical parameter |

Resistant temperature |

-40ºC to 40ºC |

|

|

Wind resistance |

210km/h |

||

|

Earthquake resistance |

Grade 8 |

||

Fast installation and can be easily relocated after the project finished, very convenient for constr...

Easy to handle in the remote mining areas (even easier than flatpack, can handle all manually), life...

Massive production capability and fast installation made the detachable to be the perfect solution d...

Ready to move in, easy to erect, convenient to relocated, affordable for temporary use.

|

No. |

Item |

CBC Detachable Container House |

Pictures |

Evolution |

Other Brand |

Evolution |

|

1 |

Steel Structure |

G355 galvanized steel beams in thickness 2.3~3mm, high structure strength and durability |

|

★★★★★ |

G235 steel beams with only painting and thinner steel materials used, low structure strength and durability |

★★★ |

|

2 |

Electrical System |

pre-installed in the roof and wall panels, save construction time and cost |

|

★★★★★ |

need to be installed onsite, cause extra onsite labor cost and more problems |

★★★ |

|

4 |

Window & Door |

pre-installed in the wall panels, save onsite labor cost |

|

★★★★★ |

need to be installed onsite, cause extra onsite labor cost |

★★★ |

|

5 |

Steel Treatment |

Advanced sand blasting equipment line, improve painting adhesion and durability |

|

★★★★★ |

outsourced processing or no pretreatment, low painting adhesion and durability |

★★★ |

|

6 |

Painting |

Advanced automatically painting line to ensure good painting quality |

|

★★★★★ |

outsourced or manually, cannot ensure the painting quality |

★★★ |

|

7 |

advanced paint technology, water-based painting available, environment friendly |

|

★★★★★ |

only oil-based painting, more pollution to the environment |

★★★ |

|

|

8 |

Prefabrication |

30-70% as per client’s requirement, save onsite labor cost |

|

★★★★★ |

around 30% or only loosen parts available, extra site labor cost |

★★ |

|

9 |

Marking |

two-dimensional code component tracking system can effectively manage each component |

|

★★★★★ |

No label or very simple label, can’t track every component |

★★ |

|

10 |

Fast Installation |

4 workers could install 1 units in one day. Offering installation manuals, videos guidance, or send people to support. |

|

★★★★★ |

Need many workers on site to sort out materials and install. no installation manual, videos guidance, couldn’t send people overseas. |

★★ |

|

11 |

Packing & Delivery |

special steel racks to protect materials within the shipping container during the long-distance transportation |

|

★★★★★ |

no packing frame, easy to cause damage, no guarantee what you can get. |

★★★ |

Packing and transportation

We use steel rack to pack all components including the steel frames, corner parts, wall panels and other accessories.

| Project Name | Hill Top Resort | ||

| Finished Time | Year 2022 | ||

| Project Place | Malaysia | ||

| Building Area | Three buildings total 378sqm | ||

| Project Description | 7 units of 3*6m detachable container house combined for one block in remote area. With extra PU sandwich planks for external wall decoration. All well prefabricated container parts are easy to be transported and assembled, extra pitch light gauge steel framed roof for better water proof. |

| Project Name | Detachable Container House Office | ||

| Finished Time | Year 2019 | ||

| Project Place | Philippines | ||

| Building Area | 60 units | ||

| Project Description | Prefabricated 3m width demountable containers built in two floors for accommodation. Some with bathroom, also include some public shower and toilet. Provided the whole package including staircase and roof system. |

| Project Name | Epidemic Prevention Isolation Camp | ||

| Finished Time | Year 2022 | ||

| Project Place | China | ||

| Building Area | 5660 units | ||

| Project Description | 3*6m detachable container house for Epidemic prevention isolation camp in China, low cost and fast installation, can be demounted and re-located or re-used. |

| Project Name | Construction Site Office Building | ||

| Finished Time | Year 2019 | ||

| Project Place | Philippines | ||

| Building Area | 80 units | ||

| Project Description | Demountable Container house for accommodation and office building in Philippines, with customized timber appearance sandwich wall panel. Our container house can be safe in hurricane |

| Project Name | Modern Design Office Building | ||

| Finished Time | Year 2021 | ||

| Project Place | Malaysia | ||

| Building Area | 240 units | ||

| Project Description | all detachable container house in 3*6m. Full glass wall make the buildings very modern and bright inside. |

| Project Name | Demountable Container Accommodation Camp | ||

| Finished Time | Year 2017 | ||

| Project Place | Philippines | ||

| Building Area | 156 units | ||

| Project Description | Accommodation blocks made of demountable container houses, four buildings in two floors. |

CBC’s design and research activity applies BIM system and Autodesk Revit software. As China Wholesale Detachable Container House Suppliers and Detachable Container House Manufacturers.Based on relevant information and requirements of the project, we establish a building model to simulate the real information about the building through digital information simulation. what’s more, we can easily present details and 3D renderings of our company’s products to all clients.

In Year 2007, we created a unique flatpack roof system Using injected PU foam as core material, which solved the problem of the balance between the tightness, the strength and the full prefabrication in the factory.

We are also the first one to use FrameCAD system to design and manufacture the light gauge steel villa in China.

We have more than 100 patents for different parts or technology innovations, such as the wall panel clips, the skirting, the corner parts…

Feel free to contact us if you have questions or wish to get a free quote on yourdream house.Please fill out the contact form below or email [email protected].